Characteristic Advantages

1. High permeability: The metal woven structure ensures good fluid permeability;

2. Flexible filtering accuracy options: from tens of micrometers to hundreds of micrometers;

3. Reusable cleaning and use: Long service life, suitable for multiple cleaning and reuse;

4. Diverse structures: can be single-layer, double-layer, or multi-layer mesh tube structures;

5. Diverse interface forms: customizable interfaces, lengths, diameters, etc. according to customer requirements;

6. Temperature and corrosion resistance: Especially suitable for harsh environments such as high temperature, acid and alkali.

Common Specifications

Parameter | Typical Range / Options |

Material | Stainless Steel 304, 316, 316L; also Monel, Inconel, Hastelloy, Brass |

Filter Media Type | Woven wire mesh: plain weave, twill weave, Dutch weave |

Outer Diameter (OD) | 10 mm – 200 mm (customizable) |

Length | 20 mm – 1000 mm (standard sizes: 100 mm, 200 mm, 500 mm, etc.) |

Mesh Size | 10 – 500 mesh (equivalent to ~2000 μm – 20 μm) |

Filtration Accuracy | 20 μm – 500 μm (depends on mesh and layering) |

Number of Layers | Single-layer, double-layer, or multi-layer (up to 5 layers) |

Support Structure | Inner perforated tube (optional), outer protection layer(optional) |

End Style | Open both ends, closed one end, threaded ends, flange ends, custom |

Connection Types | NPT/BSP thread, clamp, flange, bayonet, push-fit |

Working Temperature | -200°C to +600°C (depends on material) |

Working Pressure | Up to 2 MPa typically (higher with reinforced structure) |

Cleaning Methods | Backflushing, ultrasonic cleaning, chemical soaking |

Application Area

1. Hydraulic system oil filtration

2. Pre filtration of pipeline impurities (protecting pumps, valves, and instruments)

3. Particle interception in water treatment systems

4. Filtration of chemical fluids and viscous liquids

5. Filtering of impurities in food and beverage raw materials

6. Filtration of cooling water system in power plants

7. Aerospace and mechanical lubrication filtration protection

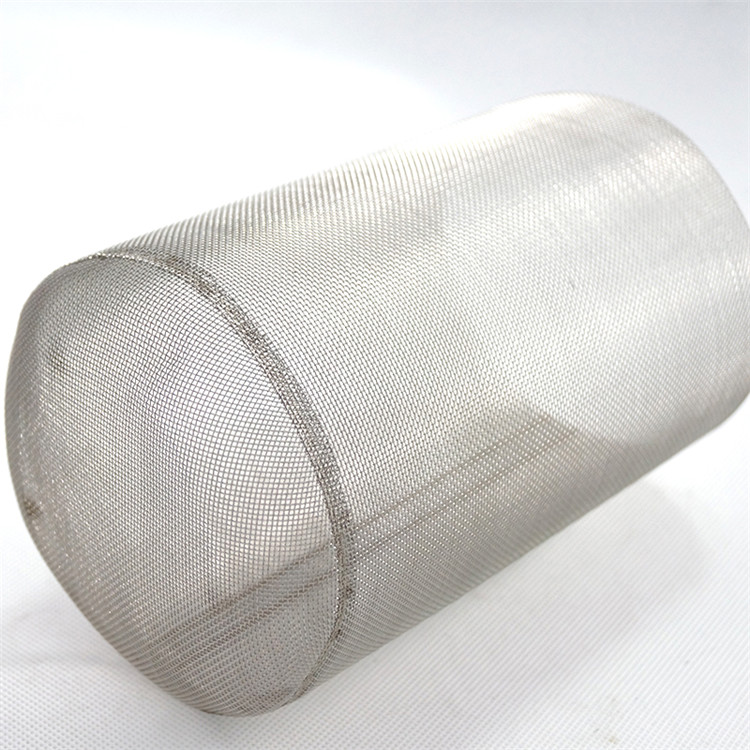

The Woven Wire Mesh Filter Tube is engineered from high-strength woven wire mesh to provide efficient filtration in a wide range of industrial processes. Acting as a durable filter cartridge, this tube effectively separates contaminants from liquids or gases, ensuring process purity and equipment protection.

Manufactured with precision weaving techniques, the mesh features uniform apertures that allow consistent flow rates while capturing fine particles. The filter tube is designed to withstand high pressures and temperatures, making it suitable for chemical processing, oil and gas, water treatment, and HVAC systems.

The robust construction of the woven wire mesh ensures resistance to corrosion, abrasion, and deformation, guaranteeing a long operational lifespan and reduced maintenance. Its modular design allows easy installation and replacement in filtration systems.

Customizable in mesh size, wire diameter, and tube dimensions, the woven wire mesh filter tube can be tailored to meet specific filtration requirements. It delivers reliable performance as a standalone filter or as part of a larger filter cartridge assembly.

With stringent quality control and advanced manufacturing, our woven wire mesh filter tubes offer consistent filtration efficiency, mechanical strength, and durability for demanding industrial environments.

Our Woven Wire Mesh Filter Tube serves as a high-performance filter cartridge designed for precise filtration in various industrial applications. Made from premium woven wire mesh, the filter tube provides effective removal of contaminants from fluids and gases, protecting downstream equipment and ensuring product quality.

The mesh’s uniform weave pattern ensures consistent filtration efficiency, allowing optimal fluid flow while trapping unwanted particles. Engineered to withstand harsh operating conditions, the filter tube offers excellent resistance to corrosion, abrasion, and thermal stress.

Commonly used in industries such as petrochemical, pharmaceutical, food and beverage, and water treatment, this filter cartridge design simplifies maintenance with easy installation and replacement. Its sturdy construction maintains shape and integrity under high pressure and temperature variations.

Available in multiple mesh sizes, wire gauges, and lengths, the woven wire mesh filter tube can be customized for specific filtration tasks, offering flexibility and adaptability.

Backed by rigorous quality assurance and advanced manufacturing techniques, our woven wire mesh filter cartridges provide reliable, long-lasting filtration solutions that enhance process efficiency and product purity in demanding industrial environments.

Please leave us a message and we will get back to you shortly.